자동 캡링 기계는 현대 생산 라인의 중요한 장비이며 안정적인 작동은 포장 효율과 제품 품질과 직접 관련이 있습니다.이 가이드는 자동 캡팅 기계와 함께 자주 발생하는 문제를 신속하게 식별하고 해결하는 데 도움이되는 세부 문제 해결 목록을 제공합니다, 다운타임을 최소화합니다.

자동 뚜?? 기계 는 정밀 한 기계 구조, 공기 시스템, 또는 서보 제어 를 사용하여 자동 으로 병 뚜?? 을 들어 올리고, 위치 시키고, 꽉 막는다.이 기계들은 식품 및 음료 같은 다양한 산업에서 중요한 역할을 합니다., 의약품, 화장품 및 화학물질에서 캡 품질은 제품의 밀폐 무결성과 안전성에 직접적으로 영향을줍니다.

준비 및 안전 체크리스트

안전 우선: 어떤 작업도 시작 하기 전 에 기계 가 완전 히 정지 되어 있는지 확인 하십시오. 전력 및 공기 공급원 을 끄고 차단 하고, 장비 에 안전 경고 라그 를 붙여주세요.

도구 들 을 준비 하라: 필요 한 모든 유지 보수 도구 를 준비 하여라. 그 들 에는 토크 리ഞ്ച് 키, 앨런 리ഞ്ച് 키 세트, 스크루드라이버 세트, 측정 칼리퍼 등 이 있다.

필수 문서: 장비 사용 설명서, 전기 도표, 예비 부품 목록 을 가까이 두고 있어야 한다.

자동 뚜?? 기계의 일반적인 고장 및 단계별 해결책

1. 잘못된 톱닝 토크

증상:

- 뚜?? 이 너무 단단하다: 병의 변형으로 이어질 수 있거나 최종 사용자가 뚜?? 을 열기가 어렵게 만들 수 있습니다.

- 너무 느슨한 모자: 제품의 밀폐와 무결성을 손상시키는 제품 누출을 유발합니다.

문제 해결 단계:

- 토크 설정을 캘리브레이트하십시오: 전문 토크 테스트 미터를 사용하여 기계를 캘리브레이트하십시오.당신의 제품의 특정 토크 요구 사항에 따라 마찰 클러치 또는 servo 모터 매개 변수를 조정.

- Pneumatic 시스템을 확인: 공기 압력이 0.6-0.8 MPa의 권장 범위 내에서 안정적으로 확인. 또한,압력 절감 밸브가 일관된 공기 공급을 보장하기 위해 올바르게 작동하는지 확인하십시오..

- 마모 및 찢어짐 을 검사 한다. 마구 머리 에 있는 마찰 패드, 잡기, O 링 을 주의 깊게 검사 한다. 이 부품 들 의 마모 는 불안정 한 토크 를 초래 할 수 있다. 필요 한 대로 교체 한다.

- 높이 설정 조정: 뚜?? 머리 의 수직 높이 를 재정형 합니다. 부적절 한 접촉 으로 인한 문제 를 방지 하기 위해 병 목 과 정확 한 접촉 을 하는 것 을 보장 합니다.

2캡 포착 및 떨어뜨림 실패

증상:

- 캡 헤드가 낙하산에서 캡을 잡지 못합니다.

- 뚜?? 이 고정되기 전에 뚜?? 이 떨어집니다.

해결책:

1캡 품질 확인: 크기가 사양에 맞는지 확인하기 위해 캡을 측정합니다. 변형 된 캡 또는 부러가있는 캡은 잡기 실패의 흔한 원인입니다.

2- 잡기 장치를 검사해

- 기계적 유형: 손잡이의 스프링 텐션이 약화되었는지 또는 손잡이 자체가 마비되었는지 확인하십시오.

- 진공 유형: 진공 선의 밀폐를 검사하고 충분한 진공 힘을 보장하기 위해 흡입 컵을 청소하거나 교체하십시오.

3. 캡 쉐이프를 청소: 캡 쉐이프에서 잔해 또는 부서진 캡을 제거합니다. 캡의 원활한 흐름을 보장하기 위해 캡의 폭을 조정하십시오.

3굽은 또는 굽은 뚜??

증상: 뚜?? 이 병 열기와 평행하지 않고 왜곡된 모양입니다.

문제 해결 방법:

- 병 품질 검사: 병이 변형되지 않았으며 모든 병 개통이 균일한 크기를 가지고 있는지 확인합니다.

- 중심 장치 조정: 병이 캡 스테이션에 들어갈 때 병이 정확하게 중심되어 있는지 확인하기 위해 병을 잡는 메커니즘 (예를 들어, 측면 벨트 또는 클램프) 을 캘리브레이트하십시오.

- 기계 중심성 검사: 매개 머리와 병 받침대, 그리고 컨베이어 벨트가 모두 완벽하게 정렬되어 있는지 확인한다. 직선 매개에 중심성이 중요하다.

- 기계 레벨 확인: 기계가 평평한 표면에 설치되어 있는지 확인하기 위해 레벨을 사용하십시오. 불규칙한 기반은 흔들림과 왜곡 된 캡을 유발할 수 있습니다.

4캡 해킹 및 차단

증상: 모자가 모자 정렬 그릇이나 배달 기구에 붙어 있습니다.

빠른 수정:

- 기계 를 즉시 중지 하십시오: 장비 를 끄고, 분류 그릇 과 기판 에서 외계 물체 들 이나 부러진 모자 들 을 제거 하십시오.

- 낙하창 간격 조절: 평탄한 통과를 보장하기 위해 낙하창의 간격과 캡의 크기를 맞추십시오.

- 정렬 디스크 를 검사 한다. 정렬 디스크 의 안내 막대 를 마모 하는 점 을 확인 하고 필요 에 따라 디스크 의 회전 속도 를 조절 한다.

5비정상적인 소음과 진동

증상: 기계 가 작동 중 에 특이한 소음 이나 과도 한 진동 을 발생 시킨다.

주요 검사점:

- 고정 장치 를 검사 한다. 기계 에 있는 모든 볼트 와 스크루 를 철저 히 검사 한다. 장기적 인 진동 으로 인해 그 들 이 풀 수 있다.

- 윤활유 및 유지보수: 기계 사용 설명서 를 참조 하여 마찰 을 줄이기 위해 베어링, 가이드 레일 및 다른 움직이는 부품 에 적당 한 양의 윤활유 를 첨가 한다.

- 구동 시스템 을 검사 하십시오. 벨트 의 긴장 을 검사 하고, 손상을 입거나 치아 가 빠진 경우 를 확인 하십시오.

6전기 제어 시스템 고장

증상: 기계가 반응 하지 않거나 움직임이 불규칙하다.

진단 방법:

- 센서 확인: 모든 광전기 센서 및 근접 스위치를 청소합니다. 먼지 또는 더럽은 신호를 방해 할 수 있습니다. 필요한 경우 감지 거리를 조정합니다.

- 배선 검사: 단말기 연결이 느슨한지 확인하고 케이블이 손상되거나 마모 된 흔적을 검사하십시오.

- PLC를 검사합니다: PLC (프로그램 가능한 논리 제어기) 상태에서 오류 코드 또는 표시등을 확인합니다.PLC 의 소프트웨어 를 통해 입력/출력 신호 를 모니터링 하는 것 은 문제 의 근원 을 신속하게 파악 하는 데 도움 이 될 수 있다.

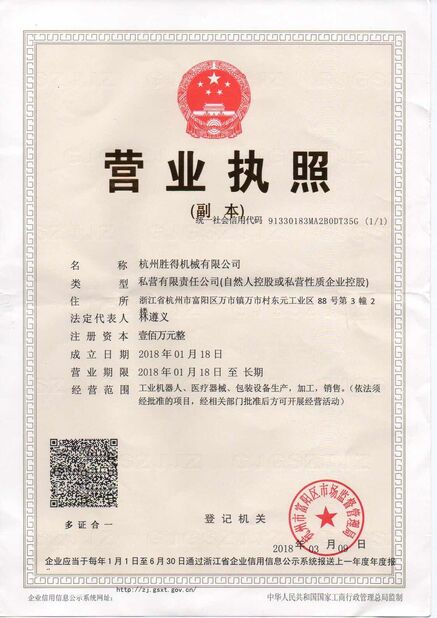

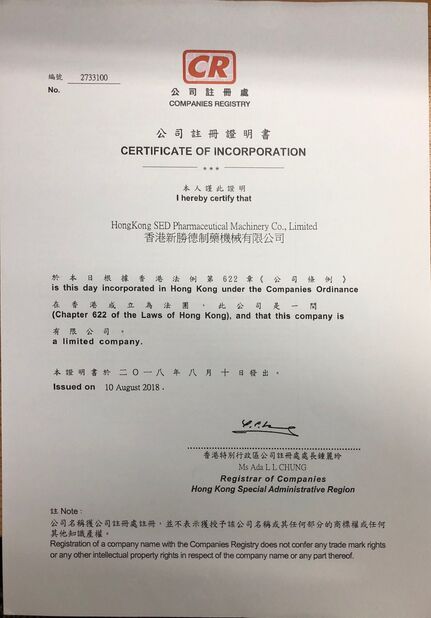

복잡한 고장 또는 핵심 부품이 교체되어야 할 경우 장비 제조업체 또는 전문 수리 서비스 팀과 연락하는 것이 좋습니다.장비 의 일련 번호 와 구매 정보 를 보관 하여 실제 의 예비 부품 과 기술 지원 을 신속 히 구할 수 있습니다.

예방 유지보수 계획

장시간 안정적인 작동을 보장하기 위해 다음 유지보수 일정을 시행하는 것이 좋습니다.

| 빈도 |

작업 |

세부 사항 및 표준 |

| 매일 |

1기계 청소 |

기계 표면 (특히 캡 헤드, 컨베이어 벨트, 레일) 을 공기 총과 천으로 청소하여 종료 후 먼지, 기름 및 제품 잔해를 제거하십시오. |

| 2공기 공급 확인 |

공기 압력이 필요한 범위 내에서 안정적으로 있는지 확인하십시오 (일반적으로 0.6 ~ 0.8 MPa); 깨끗하고 건조한 공기를 보장하기 위해 공기 필터 규제 장치에서 물을 배수하십시오. |

| 3기본 윤활 |

지정된 가벼운 윤활유를 몇 개의 주요 노출 된 레일, 실린더 막대 등에 적용하십시오. 오염 된 병이나 뚜?? 을 피하십시오. |

| 4시각 및 음향 검사 |

시작하기 전에 비정상적인 소음, 느슨한 부품, 또는 다른 명백한 문제를 위한 기본적인 검사를 수행합니다. |

| 주간 |

1고정 장치 확인 |

진동으로 인해 느슨해지는 것을 방지하기 위해 모든 나사, 볼트 및 장착판 연결을 확인하고 단단히 잡으십시오. |

| 2센서 청소 |

전원을 끄십시오. 신뢰성있는 기능을 보장하기 위해 모든 광 전기 센서 및 근접 스위치의 렌즈 / 센서 표면을 알코올 wipe로 조심스럽게 청소하십시오. |

| 3착용 부품 검사 |

뚜?? 머리 잡기, 마찰 디스크, 진공 컵, 컨베이어 벨트, 레일 같은 소모품의 마모 수준을 확인하고 남은 수명을 평가하십시오. |

| 4안전 기능 테스트 |

응급 정지 버튼과 안전 보호 장치의 기능을 테스트합니다. |

| 매월 |

1전면 윤활 |

모든 지정된 움직이는 부품 (레어링, 가이드 레일, 슬라이더, 기어) 을 사용 설명서에 따라 적절한 지방 또는 기름으로 윤활하십시오. |

| 2드라이브 시스템 검사 |

타이밍 벨트, 사슬의 긴장 및 마모를 확인하고 필요한 경우 조정하거나 교체하십시오. 원활하고 조용한 작동을 위해 모터를 확인하십시오. |

| 3토크 캘리브레이션 |

인증 된 토크 테스터를 사용하여 여러 가지 측정을 수행하십시오. 기계 표시 값과 비교하고 필요한 프로세스 범위로 캘리브레이트하십시오. |

| 4- 공기 시스템 검사 |

모든 공기 튜브 연결을 누출 여부를 검사하고 실린더를 부드럽고 강력하게 움직이도록 검사하십시오. |

| 연간 |

1봉인 교체 |

큰 수리 를 수행 하십시오. 노화 와 누출 을 방지 하기 위해 모든 주요 내부 O 반지, 밀봉 및 공기 밸브 밀봉 을 교체 하십시오. |

| 2모터 및 드라이브 검사 |

서버 모터, 기어박스 등의 작동과 정확성을 검사하십시오. 모터 냉각 팬을 청소하십시오. 밀착성을 위해 전기 단말기를 검사하십시오. |

| 3전체 기계 재정렬 |

기계 레벨의 포괄적 인 캘리브레이션을 수행하고 공장 정확성을 회복하기 위해 머리와 병의 동심성, 리프트 높이 및 기타 기계적 매개 변수를 제한하십시오. |

| 4제어 시스템 검사 |

전자기장 안의 먼지를 청소하고, 차단기, 접촉기, 릴레의 접촉을 확인하고, PLC 프로그램을 백업하세요. |

결론

의자동 캡의약품 포장 라인에서 안정적인 품질과 효율적인 운영을 달성하는 데 필수적입니다.

일반적인 고장을 이해하고 신속한 문제 해결 방법을 적용하고 예방 유지보수 계획을 따라 기업들은 생산을 최적화하고그리고 시장에서 경쟁 우위를 유지.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!